In response to the accident at the Fukushima Daiichi Nuclear Power Plant, Natural Science takes the following actions to protect the health of our customers, especially children, and to reduce their anxiety as much as possible.

- We make efforts to provide accurate information so that our safe products can be trusted and used with peace of mind.

- We conduct thorough inspections for radioactive materials in the processes of manufacturing and storing our products.

- We will never source raw materials, manufacture or store our products in the restricted areas.

Natural Science has established guidelines for standard limits for radioactive materials in foods, in order to lessen customers’ worry and anxiety about radioactive materials as much as possible.

Currently, the detection limit is set at 15 Bq/kg, and only products in which no radioactive materials are detected are shipped.

All processes of manufacturing and filling as well as radioactivity measurements are performed in cleanrooms. Each batch (production control number) of manufactured products is checked using a radioactivity measuring device mainly used for food products, and only the bulk (contents of cosmetics before being packaged) with no detectable radioactivity is used for filling.

In addition, the products that are ready to be shipped after going through all the processes are periodically subject to analysis performed by an external laboratory using a germanium semiconductor detector in order to confirm their safety.

■ Product radioactivity testing processes

-

Fill the sample into the dedicated measuring container.

-

-

Set the container in the radioactivity measuring device, and start the measurement.

-

-

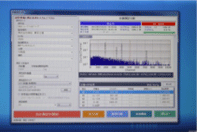

The measurement is completed in about 20 minutes, and the measurement results are output.

■ Radioactivity measuring equipment

*"Not detected" means that radioactive iodine or radioactive cesium is not present or below detection limit.

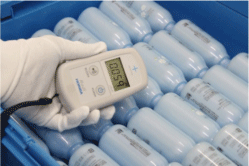

Packaging materials, such as containers and boxes used to contain the products, and labels, are measured to determine the radiation levels when they are delivered to the factory.

■ Radioactivity measuring equipment

Environmental radiation monitor PA-1000 (manufactured by HORIBA, Ltd.)

Radiation levels in and around the factory are measured every day to identify if there are any areas with high radiation levels.

■ Radioactivity measuring equipment

Environmental radiation monitor PA-1000 (manufactured by HORIBA, Ltd.)

The water used for our products is purified through a four-step filtration process (activated carbon filtration system, RO system, ion exchange purification system, and membrane filter) to produce pure water (purified water). The purified water is tested for microorganisms, PH, electrical conductivity, and other physico-chemical parameters before use, and is also measured by a radioactivity measuring device. After the test results are determined to be “not detected,” the water is used for our products.